Packaging production has long been no longer just for the technical production process, in which a substance is converted into a mailbox. It is a process, connecting, creativity, technology, and brand strategy. From the first idea and design sketches to carefully carried out of the press and of quality control — quality modern packaging not only protects the product, but also tells a story, creates a first impression, creates the emotion and help the product stand out among many others.

Consumer eyes often appreciates more quickly than the hand, so the packaging production has a lot of nuances: selected materials, construction types, printing technology, color control, finishing solutions, layout, rules and, of course, production timelines and pricing.

In this article we will discuss how packaging production develops from the idea to the finished product, what elements must influence the selections and how to ensure that prepared the packaging to meet all of Your expectations.

What starts in the package path?

Each package always starts with an idea. She is born thinking about how to protect the product, to convey the brand tone and values, and encourage purchase. From the first sketches to the final layout, this stage requires a clear plan: the color, logo, text layout and functional solutions.

The main issues that need to be answered at this stage:

- What impression is to be created? What the buyer is aimed at attracting?

- What functionality? The package must not only protect the product, but also be easily transported, to comply with sustainability standards and be comfortable in both business and the consumer.

- What is brand objectives? Whether the emphasis is on sustainability, whether the aim is to highlight the luxury, uniqueness and exquisite image?

This step is essential because it is from the initial ideas will all subsequent production decisions. It is important to keep in mind that the packaging is not only protection, but the first contact with the consumer, and therefore every decision should be well thought out.

How to choose the right materials: cardboard and its advantages

The choice of material is an important step in order to create a functional, environmentally friendly and aesthetic of the packaging. So, once the package is clear, it is necessary to choose the right material that meets both the design and product protection requirements.

The cardboard packaging has today become one of the most popular choices for many manufacturers due to their functionality and sustainability advantages.

The main cardboard advantages:

- Sustainability: paperboard is made from natural, renewable resources. Its production generally have lower CO₂ emissions than plastic or metal.

- Easy processing: simple to sort and dispose of in a paper container, making it less of a negative impact on the environment.

- Lightness: for a light weight, lower cost and the possibility to transport the flat packaging, paperboard reduces logistics costs.

- Protection for a low price: it is a material with optimum protection and price balance, sustainable and cost-effective choice for many products.

- More attractive to the consumer: on a more equal texture, better printing quality and higher aesthetic standard.

Selecting the right material, it is necessary to consider the different cardboard types, because each of them has its own advantages, depending on the package destination and product protection requirements:

- SBS (Solid Bleached Sulphate): premium class cardboard from 100 % balinto of the primary beam. Exudes impeccable baltumu, completely level surface and exceptional printing quality. Ideal for the highest value added packaging: cosmetics, parfumerijai, small technology products, gift boxes.

- GC1 paperboard: high quality multi-ply paperboard with white and level the surface, at the right detalizuotai release. The most commonly used in the cosmetic, pharmaceutical, food and luxury goods packaging, where an important visual, cleanliness, and strength.

- GC2 cardboard: economical GC1 alternative, with a white top and yellowish inside. Suitable for a wide range of products choice: tea, for lightweight electronics accessories, everyday and household goods, where is important to have good price and quality ratio.

- Kraft paperboard: the natural brown color, very sturdy paperboard for greater weight of goods, food, and frozen food packaging. Perfect for complete beverage packaging, protective and even transportinėms boxes. Because of its minimalist, natural image is often chosen organic products and trademarks, akcentuojantiems sustainability.

Selecting the right cardboard type, it is necessary to take into account its thickness. Thickness shall ensure the packaging of the strength and protection, which is especially important for optimizing the costs of transport and in order to maintain the packaging efficiency. Lengvoms goods is sufficient 250 – 300 g/m2 thick cardboard. The thickness shall ensure that the packaging is strong enough, but not too heavy. More severe of the goods recommended for use with 350 – 400 g/m2 thickness. This ensures that the packaging of the good protection of the product from damage, but at the same time maintains the logistics efficiency.

The cardboard packaging is the perfect choice for sustainability, easy processing and protection. They not only effectively protects the product but also helps in maintaining the ecological standards. The choice of appropriate paperboard type and thickness can ensure the best packaging function and reduce logistics costs.

Packaging design: from boxes to liners

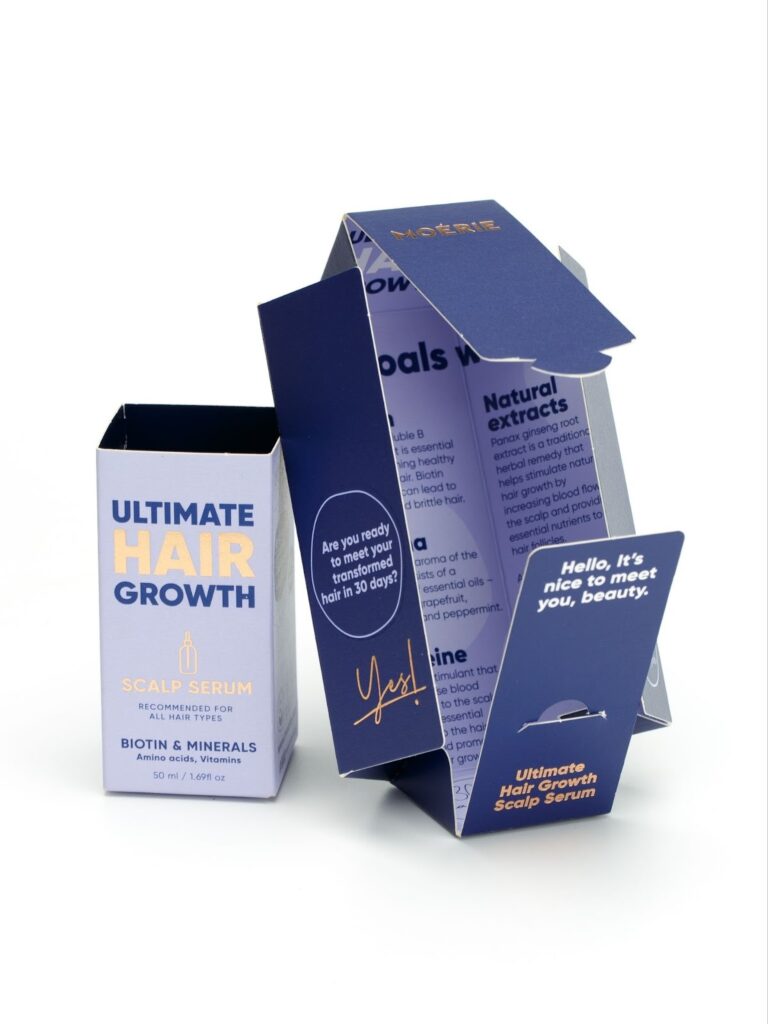

The packaging design has a great influence on product protection, user experience, overall impression and in the business of manufacturing efficiency. Properly chosen design facilitates the packaging, ensure the safety of transport and helps the product to look like neatly and attractively. Cardboard packaging production can be selected from the multitude of constructions, however, several types are particularly popular due to their functionality and versatility.

Folding box

Folding box – one of the most popular solutions to day-to-day products. They are lightweight, conveniently stored and quickly assembled, making it perfect for both small and large production quantities.

The most popular of folding boxes design:

- Straight Tuck Box (STB): top and bottom closes by inserting the tabs into the interior.

✔ suitable for lightweight products

✔ aesthetic, clean form

2. Reverse Tuck Box (RTB): top and bottom closes in opposite directions.

✔ cost-effective

✔ stability takes the shelves

3. Snap Lock Bottom (1-2-3 Bottom): the bottom consists of 4 valves which need to be "suspended".

✔ stronger than a simple tuck-in

✔ suitable for medium-weight of the product

4. Auto Lock / Crash Lock Bottom (Lock Bottom': bottom to automatically susirakina išskleidus box.

✔ very sturdy

✔ suitable for heavier products

✔ faster assembly

5. Seal End Box: top/bottom heat removable (e.g., glue).

✔ frequently used in food packaging (bulk goods)

6. Sleeve Box (Sleeve): outer sleeve + inner pouch.

✔ premium-image

✔ suitable for collections, gifts

7. Drawer / Matchbox Box (Stumdomoji): in two parts: the outer box + cushion insert.

✔ luxury impression

8. Gable Box (with handle): at the top, causing the roof/knob.

✔ food, take-away, sets

11. Display Box / Dispenser Box: opens the way to becoming the booth.

✔ venues, tea, bars so

This design is suitable for both digital and ofsetinei release, so it gives the flexibility and reliability of both the production process and daily use.

Inserts and a protective strips

Liners and inserts to give packaging more stability and procedures, in particular when the product is fragile, has several parts, or require estetiško submission.

They helps to stabilize the product during transportation, to distinguish between configuration items, create prabangesnę unboxing experience and helping to avoid plastic use and maintain a sustainable image.

Well thought-out packaging design helps to reveal the product's value and ensure that it safely and in an orderly manner to reach the user. Combining the correct type of boxes with inserts and protective inserts provide a stable, comfortable and aesthetic of the packaging, tailored for both everyday and strong, both premium and trapesniems products.

Printing and finishing: CMYK, Pantone, foil, soft-touch, drip-off and other effects

Press and finish is one of the most important packaging phases of development, as here, the board takes on not only the color, but also character. These processes require precision and creativity, that the final result would be the aesthetically appealing and meet the quality requirements. Different printing technology and finishing effects allows you to create packaging that not only protects the products, but also adds value through the visual and tactile impression.

CMYK printing

CMYK (Cyan, Magenta, Yellow, Key/Black – black) – this four-color printing system, ideal for photographs, illustrations, and complex vizualams, which need to be accurately convey the a lot of tones and nuances.

This system perfectly restores the color transitions, gradients in the storage site and detailed textures changes, therefore it is used in most packaging and graphic projects.

CMYK gives you a wide range of colors and are versatile solution for both simple and complex designs.

Pantone color

Pantone allows you to achieve one hundred percent color accuracy, because each color has its own code. This framework is particularly valuable brand, which it is important to maintain consistency and accuracy, because Pantone is guaranteed that the selected color will be the same every time, when it will be used.

Protective varnishes and UV

Protective varnishes and UV printing technology allows for packaging of the additional gloss and protection. The finish can be matte or glossy, and partial UV varnishing allows you to highlight certain design details, such as logos, symbols or drawings. UV technology also increases the resistance of the external environment and extend packaging life.

Foiling

Foiling is finishing technology, where on the packaging surface fixed with beam special foil, allowing the design of exclusivity and premium experience.

Foil may be metal or pigment:

- A metal foil has the characteristic metallic glow, perfect to reflect the light and highlight design elements.

- Pigment foil is opaque, without metallic lustre, but allows you to achieve intensive, sodrias colors.

Both types may be of different shades – not limited to gold, silver, black or holografija.

For your visual strength foiling in particular are often used in cosmetics, premium gift, perfume and alcohol packaging where the major focus on the strict and high quality impression.

Terrain (kongrevas)

Embossing technology, also known as kongrevu, helping to create the iškilius or įspaustus elements on the packaging surface. This not only adds to the design aesthetic value, but also gives a pleasant tactile sensation. The terrain can also be used to highlight the important parts, for example, logo, or trademark symbols.

Soft-touch surface

Soft-touch surface gives the packaging a special, gentle and pleasant to the surface, which is reminiscent of rubber or velvet. This finish looks elegant and gives a good quality experience. Often soft-touch finish combined with folijavimu to create contrast between the frosted and glossy surface, what it looks extremely impressive and luxurious

Selecting the suitable printing and finishing technologies, can provide a wide range of packaging designs from the subtle and minimalist to luxurious and fancy. This allows packages to adapt to both day-to-day products, and the highest quality product. By combining different apdailas, for example, the soft-touch and foil or terrains with UV lakavimu can create a unique visual and tactile effect, which helps to stand out in the competitive market.

Layout: how to prepare files for production

Layout, this is a cornerstone of the process between design and production, covering the entire technical process – from you to provide graphic elements (logos, artwork, text layout to the production of the prepared layout. Even the smallest inaccuracy can lead to additional costs or production delays, so set up correctly mockup helps to reduce spoilage and risk of errors and saves a lot of time. Technical requirements and rules apply to this process, is not complex, but compliance with them helps to ensure the smooth functioning of the production process and the objectives of the final result.

Here are some basic rules that should be followed:

- Bleed (overhangs) – requires 3 to 5 mm overlap around the edge, that after cutting, no white lines.

- The text away from the edges – it is recommended to leave 3-4 mm safety zone that the texts from entering the cutting line.

- Font of the curve – all fonts must be converted into curves, so that the printing house to see the correct characters.

- The minimum thickness of the lines – very thin the line may be lost, so safer to use at least 0.3 pt black lines.Pantone accuracy use the Pantone, the color settings should be marked as "spot colors", and does not convert to CMYK.

Well designed layout is a necessary step before starting production. Before preparing the layout of a press release always we recommend that you review the layout for the preparation of the rules or the layout preparation consult the packaging of the manufacturer.

Quality: tests, color control and sample approval

Quality control is one of the most important stages of packaging production. It shall ensure that the final packaging not only protect the product, but also meet the design, material and brand requirements. Even menkiausia error may affect product attractiveness or the functionality, therefore, the control processes are carried out at all stages of production.

Color accuracy

It is important that the colour would be the same in all tiražuose, especially if you want to maintain the brand identity. By repeating the pressing, always take into account the fact that different packaging lots colour match, examples of archyvuojame – the clients do not need to do.

The accurate color verification helps to prevent mistakes and ensure that each packaging comply with the design vision.

Prototypes and maketiniai examples

Before starting the mass production it is very important to have a physical prototype. In this way, it is verified that the design of the logic and strength shall be Tested in the lock mechanisms and bending of the local and assessing the final visual and material sensation, including freedom of the press colors and the finish, if ordered tryout production. The prototype helps to avoid surprises, allow for the adjustment of construction and design, and ensure that the final product meets all expectations.

Quality control is not just a formality, this is an important step that will ensure that the packaging is not only functional, but also aesthetic and reliable. Careful design of each stage of the inspection allows you to avoid errors and ensure that final product meets Your expectations and needs of consumers. Also, the quality of service in each production process. The process starts only with the quality of the service permit.

Terms tiražai and pricing

Packaging production deadlines, the minimum and maximum tiražai and the price is very dependent on the specific project from the packaging type of the manufacturer of the available technology, employment and other individual factors. Each project is unique, so the exact pricing is always determined individually.

| Package type | Minimum ordering quantity | Maximum pc quantity* | Price/pc | Terms** |

| Premium | It is recommended to: 1 000 pcs | There is no limit | From 0,08 € | 2-3 weeks |

| Cosmetics, perfumery | From 0,04 € | |||

| Beverage box, multipack’s | From 0,08 € | |||

| Food supplies (especially for direct contact with food) | From 0,04 € | |||

| Pharmacy | From 0,04 € | |||

| Packaging for tobacco | From 0,04 € | |||

| Advertising Products | 0.02 € | 1-3 weeks | ||

| Labels | 10 000 | From 0,005 € | ~1 week | |

| E-commerce packaging | It is recommended to: 1 000 pcs | From 0,04 € | 2-3 weeks |

As an example, we provide our standard terms, runs and prices:* Production takes place 24/7, so we can produce any amount. The price directly depends on the edition, the materials type and technology.

** Deadlines are always counted from the file fixing and placing the order, and may vary depending upon manufacturing employment.

These terms, tiražai and prices provided as a reference to help build an understanding of the production process. Each package the order is unique, therefore the final price and production time are always determined individually, taking into account the materials, technologies and manufacturing employment.

Planning a new package, we recommend that you as early as possible to consolidate the files and make a custom – this allows you to accurately plan production and ensure that your project will be completed smoothly, on time and under budget

The most common errors and how to avoid them

Packaging production error usually occurs prior to the start of the press. Even small details can lead to inaccuracies around the tiraže, it is therefore very important to carefully prepare mockups and prototypes. Below are the most common mistakes and tips to avoid them.

Layout files without overlap

Allowance (bleed) – this is extra edge around the design, which prevents the white lines after cutting. If the files do not overlap, the press may remain in the white bar or inaccurate capture of design elements. Solution: always add 3-5 mm with ultimately worn components all over the layout edge and make sure that the main elements from entering the cutting zone.

Inaccurately referred to Pantone colors

Pantone color shall ensure that the selected color are exactly the same in each of the press in the party. If the colors are not accurate or incorrectly marked, the final result may differ from the design vision. Solution: use the "spot colors" of the certificate and always check the colors before placing a file in a press release.

Too thin cardboard to heavier products

Through the thin paperboard may not provide sufficient protection, and warp during transport. This is especially true for heavy or fragile products. Solution: select the proper thickness of the paperboard under the weight of the product and the conditions of transport (e.g., 350-400 g/m2 heavier products).

Unverified prototype

Before mass production, the prototype helps to assess the strength, the lock mechanisms and the design logic. In general the prototype can lead to surprises and mistakes around the tiraže. Solution: always gaminkite at least one maketinį model or prototype and carefully try.

Cardboard packaging production with Trustpack

Cardboard packaging production – it is much more than a technical process. Here combines design, technology, materials and functionality, and each and every step, from design to apdailų, shaped by the user's impression about the product and of the same brand. Well thought-out packaging not only protects the product but also enhances its value, helps to stand out on the bookshelf and in which the reliability of sense. When you understand all of the packaging the way from concept to production, making it easier to pick a reliable production partner, take accurate decisions and avoid errors. Such a package is not only for product protection, but also as an essential sales and the image of the part.

If you are planning a new product packaging or search for a more efficient decision for existing packaging, Trustpack can prepare a detailed offer within 24 hours.

Contact Trustpack and get a solution tailored specifically for your product.