Suitable for food packaging is determined directly by the product freshness, user security and brand image. However, businesses are often faced with a dilemma: to choose practicality, aesthetics or sustainability? In this article you will find clear criteria to understand what package best suited for different food products.

Understand what features need to be for your product

There is no single universaliausios the packaging of all food products is the most appropriate solution depends on the product properties. Different products require different protection, designs and materials of the mix, so it is important to assess what is best for your product: moisture protection, fragilité, temperature resistance or the visual attractiveness.

Products with the fat, moisture or intensive scent

Fat and moisture-sensitive products necessary for barrier packaging, which protects from percolation, smells, migration and ensure product freshness. This is especially important riebiems baked goods, cheese or nuts. Typical solutions: * cardboard packaging with barjeriniais layers, in addition to the plastic, which protects against moisture.

Brittle and easily damaged products

Fragile products, such as confectionery or desserts, require additional structural fastening. Important reinforced edges, partitions or special box design, which protects the products during transport and during storage. Such packaging shall ensure that the product reaches the consumer intact and will retain its aesthetic value.

Frozen Food Products

Products supplied frozen, necessary packaging, resistant to temperature fluctuations. Non-standard construction and material combinations helps to protect the product from deformation, moisture exposure, or 'freezer burn' of the refrigeration case. Such a package suitable both for manual and automatic packaging and ensure product safety throughout the supply cycle.

After evaluating the fat, moisture, fragility or temperature sensitivity, you can select designs and materials, which not only protects the product, but also improves the user experience and strengthen the brand image. This is the first step in creating a professional, safe and attractive food packaging.

Consider the hygiene and safety requirements

When choosing food packaging, safety and hygiene are the cornerstones of the criteria. Even short-term contact with food may present a risk if the package do not have the appropriate certificates. It is therefore important to ensure that the manufacturer can confirm the packaging safety and compliance standards such as the FSSC 22000.

Certificates for food contact – what do they mean?

Packaging for direct contact with food, must have the appropriate certificates, such as FSSC 22000. It is an international standard, to ensure that the manufacturing process follows strict hygiene and food safety requirements. Even short-term product contact packaging in addition to the certificate, the choice may present a risk from health problems to the consumer before the legal consequences of the business. Therefore, the certified material is necessary, even if the product quickly consumable.

The inner side of the press

Sometimes businesses want to pack on the inner side of print logos or information. Internal press fit, when the product is dry, and neriebus, and contact with food long term. However, long-term storage, fat, or moisture, in the case of an internal press may be inappropriate, because the paint can migrate into food and be detrimental to the quality or safety. Also, the press must be coated barrier – with varnish or plevele.

From the security and hygiene of both the product quality and user confidence. When choosing manufacturers that have the certificates, such as FSSC 22000, and uses safe, food-the right paint, you can be sure that the package meets the requirements of the law and helps to strengthen your brand reputation.

The package selection according to product category

Food packaging has to be tailored to the specific category – one properties suitable for konditerijai, other bulk products or frozen products. Properly chosen packaging not only protects the product but also enhances its visual attractive and user experience.

Confectionery packaging

Confectionery important not only for protection but also aesthetic appearance. Brittle products such as desserts, requires specific confectionery packaging with the bulkheads, which maintains its shape and protects it from collision during transportation. Boxes helps the user to clearly see the product and beautiful design reinforces the brand image.

Example: ,,Rūta’ machines box with visinio liner decision, confirmation, and allowing the safe transport of desserts. The packaging manufacturer: Trustpack.

Coffee, tea and bulk products packaging

These products particularly important for protection from moisture and flavours of the migration. Barrier the package for bulk food products helps keep the flavour and quality, ensuring that the bulk of the products are not exposed to environmental factors. Appropriate design also facilitates storage and transportation.

Example: ,,Bonduelle’ košių packaging to protect the product. The packaging manufacturer: Trustpack.

Frozen products packaging

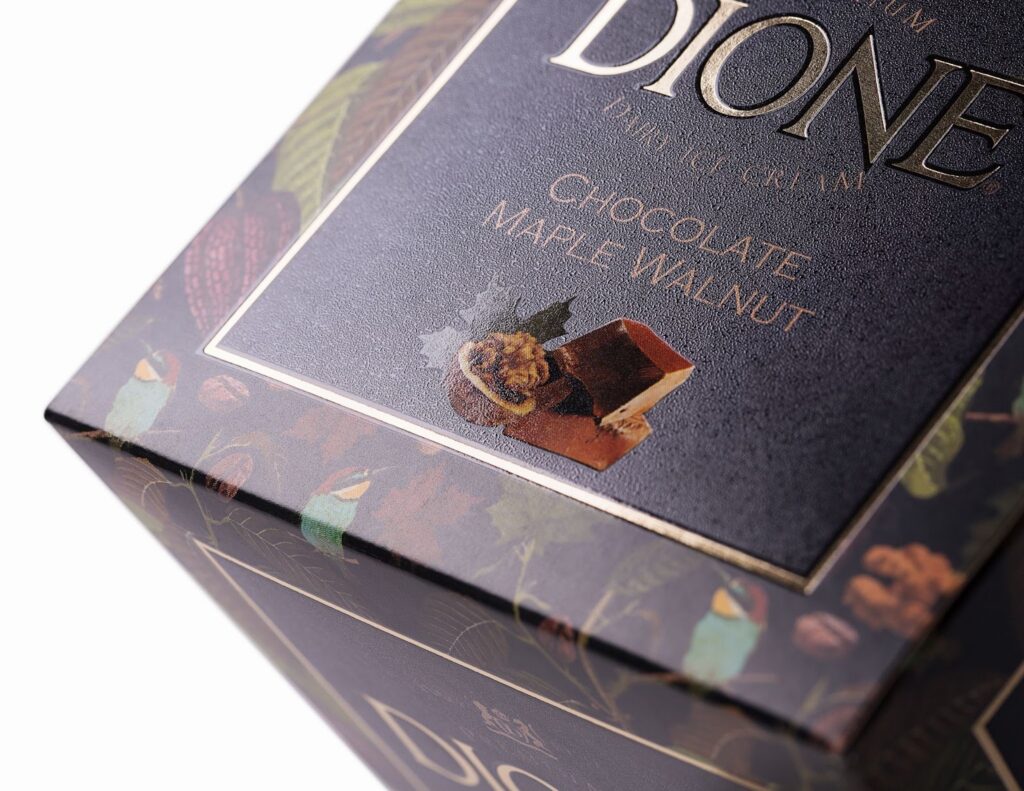

Frozen food packaging particularly important for the resistance to moisture, frost and mechanical damage. The packaging shall be certified for direct contact with food, guaranteeing hygiene and safety throughout the use cycle. The design has a stable product storage, to protect from percolation, smells, migration and keep the shape of the transport and refrigeration process.

Example: ,,Dione ice cream packaging, protects the product from humidity and cold. The packaging manufacturer: Trustpack.

Direct Food Contact Packaging

This packaging for products which come into contact directly with food – from meat and fish to desserts. Direct Food Contact Packaging must be made of certified materials to ensure the hygiene and safety of total consumption during the cycle.

Example: ,,Rūta’ packaging. The packaging manufacturer: Trustpack.

Selecting the right packaging according to the product category, you can ensure not only the safety and freshness, but also to strengthen the brand image and user experience. Appropriate design and features helps to distinguish the product in the market and customize the packaging of both the logistics and convenience to the user.

Structural solutions efficiently in the production of efficient logistics and sales promotion

Food packaging not only protects the content, but also help to optimise the production, storage and sales processes. Appropriate design can save time packing lines, to reduce the risk of breaches and improve the final product to the consumer.

Automatic bottom (quick shape)

Automatic bottom design allows the boxes to quickly and reliably collect, which is especially important for production lines with large print runs. Such a decision shall ensure that the box will be steady considered to be from the first to the last product of the packing phase, reduces labour costs and helps maintain a consistent delivery of products.

4/6 corners design

This construction provides additional stability of boxes, especially when they are considered heavier or non-standard shaped products. 4/6 corners of the package helps to reduce the strain on the risk during transportation, and ensure safe products in the possession of both warehouse and retail outlets.

Partitions and inserts (trapiai production)

Fragile products, such as desserts or household, requires additional protection. Partitions and inserts helps keep the individual elements, protect from collision and deformation. Such a design ensures that the product reaches the consumer intact and maintains the aesthetic appearance.

Gluing, folding and crossing accuracy — why is it important?

The objectives of the gluing, folding and crossing ensure the packaging form stability and longevity. Even small errors in percent can lead to violations or nepatogų use. Modern technology allows the production of complex structures, while maintaining a high level of quality, irrespective of product type or size.

Properly chosen design not only protects the product, but also optimizes the entire supply chain – from production to sales. An investment in functional design solutions help businesses reduce losses, increase efficiency and improve the user experience.

Sustainability: how to choose more sustainable food packaging?

Sustainability an important criterion for both small and large food businesses. Businesses often ask how to combine a green solution with product safety, freshness and an attractive design.

Recyclability is one of the sustainable packaging advantages, however, it is important to evaluate characteristics of the product. The cardboard packaging provides sufficient strength and protection against moisture and mechanical damage, so it can be practical and environmentally friendly solution for many food products.

Cardboard food packaging solutions

Appropriate food packaging choice requires understanding of the characteristics of the product, hygiene and safety requirements and transportation conditions. Organic solutions such as cardboard packaging with certified materials, helping to reduce environmental impact, while maintaining product quality and consumer trust.

It is important to select the reliable manufacturers, who can offer certified and tested solutions, which not only ensures product safety, freshness and adequate user experience, but also increases the efficiency of the business. If you have questions about a specific product or want to discuss the most suitable packaging solution contact and receive a quote within 24 hours.

.